-

MATCHING MATERIAL

Check by following Stock Assembly NoteWarehouse, Production Executive & QC Checking(Material is ready on the pre-preparation area)

-

TAKE THE SAMPLE

Take the sample appreaand confirm is okCompare with customer confirmation sampleOperator & OC Checking(Ensure the product color and fragrance is ok)

-

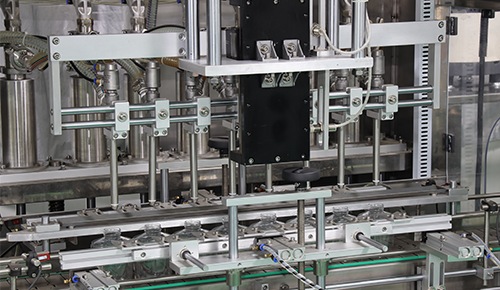

AUTO FILLING PROCESS

Material load into tank Visual Inspection Operator & OC Checking(Ensure the component weight and quality)

-

COOLING PROCESS

Putting products goes into the cooling box Visual Inspection Operator & QC Checking(Ensure product cold setting forming)

-

SEALING JAR

Visual Inspection Operator Checking(Air isolation, to ensure that the product is not volatile.)

-

PRINTING CODE

Print Batch No. Visual Inspection Operator & QC Checking (Ensure batch no coding and printing of packing productis record accordingly)

-

STICKING LABEL

Sticking the label Visual Inspection Operator & QC Checking(Ensure each piece have sticker.)

-

PUT DOUBLE SIDE TAPE

Putting double side tape Visual Inspection Operator & QC Checking(Ensure each piece have double side tape.)

-

COVERING LID

Covering the lid.Visual Inspection Operator & QC Checking(Ensure each piece have lid.)

-

FINAL PACKING CARTONING AND PALLETING

Visual Inspection Counting and 100% weight checking per cartonon finished good carton before pass to Warehouse.Operator & QC Checking(Ensure the packing quality)

-

END

Finished goods will kept on the temporaryfinished good area.